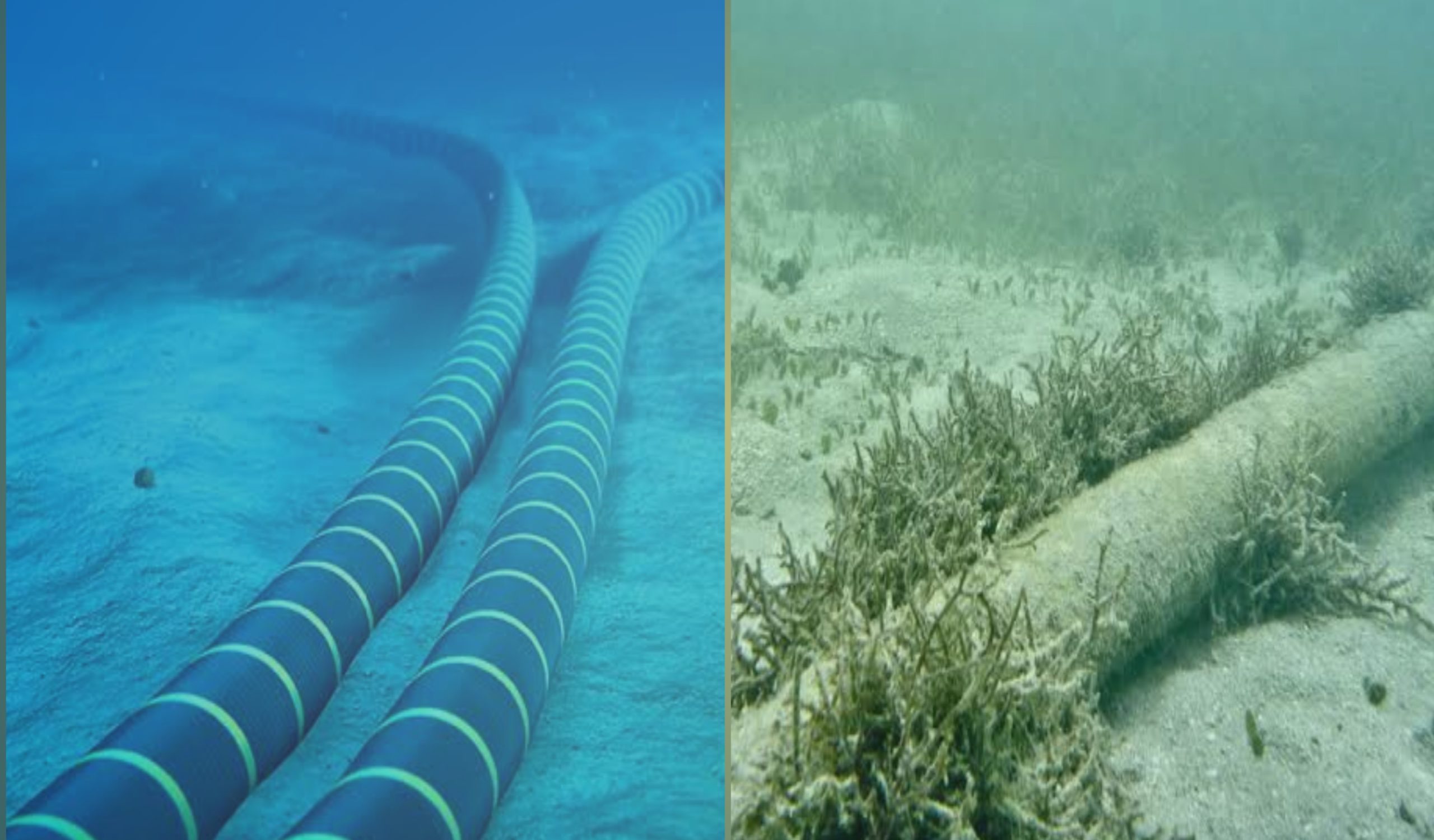

The two large subsea cable systems scheduled by Google and Meta are inclined to be game-changers for African telecoms, according to TeleGeography.

Africa is going through a mini cable explosion, with eight subsea systems expected to go live in two years.

However, only Google’s Equiano and Meta’s 2Africa will bring considerable new capability to African telecom hubs, TeleGeography senior research manager Patrick Christian said.

Other stakeholders such as the India Europe Xpress (IEX), and the Peace Cable, will reach just one or two African locations on their way to other goals.

The two current systems by the US internet giants now under construction, are their first in Africa and appear set to disrupt both the retail and wholesale markets.

“They’re the game-changers that people are monitoring,” Christian told Light Reading.

Apart from adding a downpour of fresh capability, the two new players will drive competition and will similarly insist on open access on cable docks and backhaul.

“It’s in their best interests,” Christian said.

Ripe for expansion

Africa is ripe for another round of capability expansion. It has had the world’s quickest bandwidth growth in modern years, with a four-fold expansion realized within the year 2017, and 2021, according to TeleGeography numbers.

However, the continent’s nations appear low on the global speed rankings. Gabon and Egypt are the highly-ranked in the fixed-broadband at 89th, and 83rd respectively. While Togo is the highest in mobile, coming in at position 54.

Named after the 18th-century Nigerian abolitionist Olaudah Equiano, Google’s Equiano will run from Portugal to South Africa through Togo, Nigeria, St. Helena, and Namibia. It comes with a design capability of 144 Tbps.

Initially scheduled to go into service in early 2022, it is presently expected to be authorized in Q4.

In Africa’s largest economy- Nigeria, the cable is predicted to cut down a fifth of retail Internet prices and enhance bandwidth six-fold, according to economic impact analysis.

Google defines it as providing at least 20 times more bandwidth compared to any other African cable.

That’s a substantial increment, although, it’s’ ready to be outweighed by Meta’s 180Tbps 2Africa system – at 45,000 km, it will be the world’s longest subsea cable.

2Africa will make 46 docks and link 33 countries, running the length of Africa’s east and west coasts. And similarly with an extension connecting India, Pakistan as well as the Gulf states. Among the African nations, it will connect Kenya, South Africa, Tanzania, Mozambique, and Nigeria.

It first landed in Genoa in April and appears likely to go live in late 2023 or 2024.

Certainly, Google and Meta aren’t strangers to the subsea capability business. Many US internet giants including Amazon, Apple, Microsoft, and Netflix, control traffic on the world’s main cable systems. They account for 76% of trans-Pacific traffic and 92% on Atlantic routes.

However, in Africa, they account for less than half of the internet. Although, that is about to change.

Cable FAQs

Here are the frequently asked questions about cables, according to aakash Powertech pvt:

What are the different elements of a Cable?

Basic information about cable components & construction.

Conductor

The conductor is a current-carrying element made up of Aluminium or Copper with a specific cross-section for the assigned rating, having resistance/km within certain specified limits.

Electrical Insulation (dielectric)

Insulation is provided over the conductors to electrically isolate them from one another. Various types of insulating materials used are PVC, XLPE (Cross-Linked Polyethylene), Rubber, etc.

An insulated conductor is termed a Core. A cable may have one or more cores. In a multiple-core cable, the cores are helically stranded together. In twin, three & multi-core cables, the cores are laid up together with a suitable lay; the outermost layer has a right-hand lay and the successive layers are laid in opposite lay directions.

Inner sheath (bedding)

Cables with stranded cores are provided with Inner Sheath applied either by extrusion or by wrapping. It is ensured that the shape is as circular as possible. The inner Sheath is so applied that it fits closely on the laid-up cores & it should be possible to remove it without damage to the insulation. The thickness of the Inner Sheath is specified in relevant standards and is based on calculated diameter over laid-up cores.

Armour

A wire, strip, or tape applied helically over the cable, to protect the cable from penetration by sharp objects, crushing forces, and damage from rodents or boring insects are termed Armour.

Armour is applied over the insulation in case of single core cables & over the inner sheath in case of twin, three & multi-core cables.

Outer Sheath

The outer sheath /Jacket is usually an extruded plastic cover over the laid-up or armored core. PVC is a common sheathing material. The outer sheath provides mechanical, thermal, chemical, and environmental protection. No electrical function is assigned to the Outer sheath. The color of the outer sheath is normally black.

What are the cable designations types?

Nomenclature of the cables What are different cable types and categories?

Cables can be divided into a large number of types based on a combination of classifications as follows:

- Based on the voltage ratings as low voltage, high voltage, extra high voltage cables, etc.

- Based on the conductor material, Copper conductor or Aluminium conductor.

- Based on the insulating material as PVC insulated, Rubber insulated, XLPE insulated, etc.

- Armoured or Unarmoured cables

- Based on the sheathing material, such as PVC Sheathed, Rubber Sheathed, Lead Sheathed, Aluminium Sheathed, etc.

- Based on the number of cores as single core, two core, three core, three-and-a-half core, four core, multicore, etc.

- Based on the cross-section of the conductor.

- Based on the type of conductor, solid, stranded, sector shaped, etc.

From the above, it is evident that the types of cables will differ widely depending on various factors involved. To facilitate identification and description of the type of cable it is general practice to adopt some form of type designation. With these designations, it becomes easier to convey in a few words the right type of cable.

What is the difference between XLPE and PVC cables?

The important difference is the extra toughness of insulation and, in particular, the ability to withstand high temperatures without deformation due to mechanical pressure. The better physical properties of XLPE enable the insulation thickness to be reduced and hence the overall size of the cable. The continuous temperature rating is increased from 70°C to 90°C and the temperature for short circuit ratings for the cable from 160°C to 250°C.

In general, XLPE insulated cables are a competitive alternative to PVC cables for industrial use and Paper insulated cables for public supply systems.

What is screening in cables and why is it required?

Screening in Cable

Electrical Screening is necessary only for cables with phase voltage > 1 kv and fulfills the following functions.

- Potential grading and limiting of electrical fields

- Conduction of charge and discharge currents

To satisfy these functions, the screening normally comprises a combination of conducting layers with metallic elements.

The magnitude of electric stress and the degree of sensitivity of the insulation material against partial discharge govern the type of screening of the insulation with conducting layers.

Above certain voltages, as a means of containing the electrical field within the insulation, semiconducting screens are applied over the conductor & insulation. Screens are provided to achieve symmetrical dielectric fields within the cable structure & carry current during short circuits. By this, it is possible to eliminate any electrical discharges arising from air gaps adjacent to the insulation.

The coefficient of expansion of polyethylene & EPR is approximately ten times greater than that of either Copper or Aluminium, and when the conductor is at its maximum operating temperature of 90°C a sufficiently large gap is formed between the insulation and the surface of the conductor to enable electrical discharge to occur. This discharge site & any others which are formed around a conductor when the conductor is bent can be eliminated by applying a semiconducting layer over the conductor. Similarly, any discharges arising from air gaps between laid-up cores can be nullified by the use of a screen over the insulation.

During the early 1960s, semiconducting tapes were applied to the conductor but these have since been superseded by an extruded layer. This has the advantage of providing both a smoother finish and, as it fills the interstices between the wires, a circular envelope around the conductor. By reducing the concentration of the flux lines around the individual wires, the electrical stress around the conductor is reduced by between 10% to 15%. The semiconducting layer is compatible with, and bonds to, the insulation, and a nominal thickness of 0.7 mm is typical.

What is the criterion for selecting a particular type of conductor?

The conductor is a current-carrying element made up of Aluminium or Copper with a specific cross-section for the assigned rating, having resistance/km within certain specified limits.

Conductor selection depends on various parameters like current carrying capacity, system voltage, voltage drop, flexibility, shape, and economics.

The most commonly used metals are Copper and Aluminium.

Resistance (R) of a conductor is inversely proportional to the area of cross-section and is given by :

R= þ x l / A

Where

þ= Resistivity of the conductor material.

l= Length of the conductor.

A = cross-sectional area of the conductor.

What are the different types of insulating material?

List the important properties of cable insulation. What are thermoplastic and thermoset materials?

Insulation is provided to electrically isolate the individual cores from one another. The applied insulation must perform adequately in the specified temperature range, and its dielectric strength should be sufficient to sustain the electrical stresses.

Cable insulation should have:

- High Dielectric Strength

- Low dielectric constant

- Good Mechanical properties

- Resistance to Ageing

- High temperature withstand ability

Insulating materials are classified as thermoplastic or thermoset. Thermoplastic materials lose their form upon heating. Thermoset materials maintain their form despite heating. Various types of insulating materials used are PVC, XLPE, Rubber, Impregnated Paper, etc.

Polyvinyl Chloride (PVC)

Polyvinyl chloride (PVC or vinyl) is a thermoplastic. PVC compound is the standard insulation for cables rated at 11000 volts or less & sheathing of the entire range of cables. PVC compound is a mixture of PVC resin, plasticizer, fillers, stabilizers, lubricant, and pigment. The quantity and type of each ingredient determine its properties.

A broad range of electrical, physical, and chemical properties is possible. PVC has good electrical properties. It is tough and resistant to flame, moisture, and abrasion. Resistance to ozone, acids, alkalis, alcohol and most solvents is also adequate. PVC can be made resistant to oils and gasoline.

PVC has the disadvantage of having a high dielectric constant and dissipation factor. Also, plasticizer loss can cause hardening and cracking.

Crosslinked Polyethylene

Crosslinked polyethylene (XLPE) is a thermoset. It is produced by compounding PE (polyethylene) with a crosslinking agent, like organic peroxide. The molecules of polyethylene are “crosslinked”, forming an interconnected network. The terms “cured” and “vulcanized” are also used for “cross-linked”.

Elastomer

Elastomeric materials are used for insulation and sheaths. They are applied mainly where the product has to be particularly flexible. A wide range of elastomers is nowadays available to the cable industry. This makes possible the manufacture of compounds with specific properties, such as abrasion and oil resistance, weather and heat resistance, and flame resistance, combined with good overall electrical and mechanical characteristics.

The classical elastomeric material, natural rubber, has declined in significance in recent years. In its place, the synthetic elastomers produced by the co-polymerization of ethylene and propylene are constantly finding new areas of application in cable engineering. These copolymers are generally known as EPR.

Rubber was the first insulant to be used in Electric cable manufacture but gave way to other insulants like paper, PVC, XLPE, etc. Rubber is still considered the preferred insulation for flexible cables and cables where a very small bending diameter is desired.

Paper

Paper tapes of specific thicknesses and suitable widths are lapped around the conductor. The thickness of built-up insulation depends on the rated voltage of the cable. Paper-insulated cores are dried and impregnated using a mass-impregnated non-draining compound.

What are the functions of the conductor/insulation screen and the material used?

The function of the Conductor / Insulation Screen

The conductor shield is a layer of semi-conducting material. Semi-conducting materials do not conduct electricity well enough to be a conductor but will not hold back voltage.

It “smoothes” out the surface irregularities of the conductor. The conductor shield makes the voltage on the inside of the insulation the same. Industry specifications define the performance of conductor shields. Good insulation shields are extruded in tandem with the insulation.

The insulation shield consists of two components. These components are the extruded (auxiliary) shield and the metallic (primary) shield.

The extruded shield consists of a semi-conducting layer similar to the conductor shield. It makes the voltage on the outside of the insulation the same.

The primary shield can consist of metal tape, drain wires, or concentric neutral (CN) wires. Grounding the primary shield makes the voltage on the outside of the insulation ground. The Copper of the shield is usually bare but may be coated with lead or tin. Some primary shields consist of drain wires and tape. Aluminum and lead can also be used as shields.

Concentric neutral wires serve a two-fold purpose. They function as the metallic component of the insulation shield and as a conductor for the neutral return current. Their cross-sectional area must be sized to function as the neutral conductor.

Cables with PVC Insulation

The inner conducting layer consists of PVC compound having high carbon black content. For the outer conducting layer, a cover of conducting tapes is preferred.

Cables with PE or XLPE Insulation

Because of higher sensitivity to partial discharge, the reliable well adhesive gap and cavity-free bonding to conducting layers are of greatest significance. The inner conducting layer consists of a polymer compound made conductive by adding carbon black. And the outer conducting layer is formed by a semi-conducting compound along with semi-conducting tapes.

Now you why Google, and Meta Cables will be ‘game-changers’ for Africa. Similarly, you’ve got the answers to the frequently asked questions about cables.